- Преобразователи расхода жидкости турбинные HELIFLU TZN, HELIFLU TZN CUS

- Скачать

- Информация по Госреестру

- Назначение

- Описание

- Преобразователи расхода жидкости эталонные турбинные HELIFLU TZ-N

- Описание HELIFLU TZ-N:

- Предусилитель fh710co для преобразователя расхода heliflu tz n

- Applications

- Features

- Master Meter instrumented spool piece

- Cartridge concept

- Robust CUS Bearing

- Outstanding Oil Calibration Laboratory

- Wide and evolutive range of flowmeters

- Master Meter instrumented spool piece

- Certified Meters

- Light and compact

- Easy «no expert» maintenance

- Compact and portable devices for easy military use

- Highest international quality standards

- Large choice of flange types

- Choice of number and position of outputs pick ups

- Readers flexible installation

- Bi-Directional Measurements

- Quick response time

- Sustainability over decades

- Fine Spirits Metering Stations

- Mastered technology

- Low Pressure Drop

- Qualified against the most severe environmental conditions

- Light Weight

- Accuracy and repeatability

- Compact

- Coolant Fluid Leaks

- Downsizing

- Large Flow Rates

- Low Pressure Drop

- Qualified againt most severe environmental conditions

- Accomodates different types of fuel

- Real time information

- Accuracy for military

- Low cost of ownership

- Calibration with real fluid

- Flexibility

- Sturdiness

- Replaceable cartridge

- Outstanding pulse stability and repeatability

- Stable & repeatable measuring meters

- Miniaturized flow metering solutions

- COFRAC ILAC ISO17025 Certifications

- Versatile technologies

- Reliability

- Robustness for test bench & military operation

- Rugged CUS design

- ROBUSTNESS

- Full bore design

- Superior to other technologies

- Miniaturization of meter components

- Reliability of embedded equipment

- Bi-directional conception

- Cartridge concept

- Robust CUS Bearing

- Outstanding Oil Calibration Laboratory

- Wide and evolutive range of flowmeters

- Master Meter instrumented spool piece

- Certified Meters

- Light and compact

- Easy «no expert» maintenance

- Compact and portable devices for easy military use

- Highest international quality standards

- Large choice of flange types

- Choice of number and position of outputs pick ups

- Readers flexible installation

- Bi-Directional Measurements

- Quick response time

- Sustainability over decades

Преобразователи расхода жидкости турбинные HELIFLU TZN, HELIFLU TZN CUS

В комплекте с электронными блоками обработки информации, вычислителями расхода, измерительно-вычислительными комплексами, измерительно-вычислительными контроллерами, предназначены для измерений объемного расхода и объема жидкости.

Скачать

Информация по Госреестру

| Основные данные | |

|---|---|

| Номер по Госреестру | 46057-14 |

| Наименование | Преобразователи расхода жидкости турбинные |

| Модель | HELIFLU TZN, HELIFLU TZN CUS |

| Класс СИ | 29.01.03.01 |

| Год регистрации | 2014 |

| Методика поверки / информация о поверке | МИ 3380-2012 |

| Межповерочный интервал / Периодичность поверки | 1 год |

| Страна-производитель | Франция |

| Примечание | 23.07.2014 утвержден вместо 46057-11 |

| Информация о сертификате | |

| Срок действия сертификата | 23.07.2019 |

| Тип сертификата (C — серия/E — партия) | C |

| Дата протокола | Приказ 1115 п. 42 от 23.07.2014Приказ 130 от 25.01.11 п.01 |

Производитель / Заявитель

Фирма «FAURE HERMAN SAS», Франция

Route de Bonnetable BP 20154 — 72406 La Ferte-Bernard Cedex — France. Тел.+33 (0)2 43 60 28 60, факс +33 (0)2 43 60 28 70 www.faureherman.com, E-mail: fhprojects@idexcorp.com

Назначение

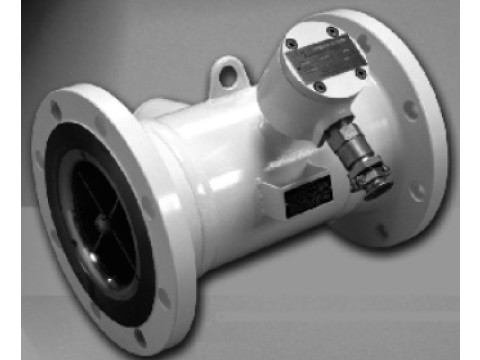

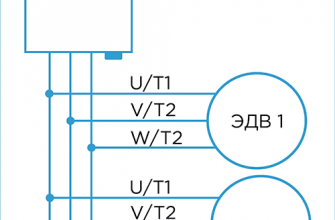

Преобразователи расхода жидкости турбинные моделей HELIFLU TZN, HELIFLU TZN CUS предназначены для измерений объемного расхода и объема жидкостей и преобразования измеренных значений в числоимпульсные сигналы.

Описание

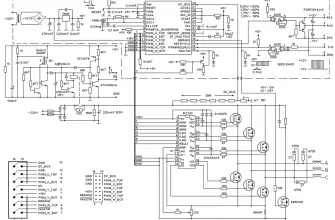

Принцип действия преобразователей расхода жидкости турбинных моделей HELIFLU TZN, HELIFLU TZN CUS основан на преобразовании поступательного движения жидкости в проточной части преобразователя расхода во вращательное движение его ротора, скорость вращения которого пропорциональна объемному расходу, а число оборотов пропорционально объему протекающей жидкости через преобразователь расхода. При вращении ротора и прохождении постоянных магнитов, размещенных на лопастях ротора, возле магнитоиндукционного датчика, в чувствительном элементе магнитоиндукционного датчика наводится электродвижущая сила, преобразуемая магнитоиндукционным датчиком в последовательность электрических импульсов, количество которых может быть измерено и преобразовано в значение объема жидкости устройством обработки информации, применяемого совместно с преобразователем расхода. Частота следования импульсов пропорциональна объемному расходу жидкости, количество импульсов пропорционально объему жидкости.

В состав преобразователей расхода жидкости турбинных моделей HELIFLU TZN, HELIFLU TZN CUS входят следующие основные части: корпус, измерительная камера (съемная), ротор и магнитоиндукционные датчики.

Преобразователи расхода жидкости турбинные моделей HELIFLU TZN, HELIFLU TZN CUS имеют взрывозащищенное исполнение со следующей маркировкой взрывозащиты: 1ExdIICT6. T1, 0ExiaIICT6. T1, 1ExibIICT6.. T1, 1ExdIICT6 .. T3, 0ExiaIICT6.. T3, 0ExiaIICT6. T5.

Минимальная длина прямолинейного участка до преобразователя расхода не менее 7 DN, после преобразователя расхода не менее 5 DN.

Общий вид преобразователей расхода жидкости турбинных моделей HELIFLU TZN, HELIFLU TZN CUS представлен на рисунке 1

Метрологические и технические характеристики преобразователей расхода жидкости турбинных моделей HELIFLU TZN, HELIFLU TZN CUS приведены в таблицах 1 и 2. Таблица 1

Параметры измеряемой среды (жидкости):

— кинематическая вязкость1), мм2/с (сСт)

— номинальное давление2), МПа

— содержание свободного газа

от 0,1 до 350 от минус 45 до плюс 180 2,0; 5,0; 10,0; 15,0; 25,0 не допускается

Диапазон измерений объемного расхода в рабочих условиях, м3/ч

Пределы допускаемой относительной погрешности, %

углеродистая сталь; нержавеющая сталь

— температура окружающей среды, °С

— относительная влажность окружающей среды, %

до 95 % при 35 °С без конденсации влаги от 84 до 106,7

Напряжение питания (источник постоянного тока), В

Частота источника постоянного тока, Гц

Средний срок службы, лет, не менее

1) По специальному заказу возможно изготовление для жидкостей с вязкостью до 1000 мм2/с.

2) В зависимости от варианта исполнения.

3) При одинаковом значении диапазона кинематической вязкости измеряемой среды при калибровке и в условиях эксплуатации. Минимальное количество импульсов при измерении объема без применения импульсной интерполяции 10000.

4) Динамический диапазон измерений объемного расхода в рабочих условиях определяется в процессе калибровки (10:1).

Источник

Преобразователи расхода жидкости эталонные турбинные HELIFLU TZ-N

Заинтересованы HELIFLU TZ-N?

Нажмите кнопку «Отправить заявку » и оформите заявку на данный товар. При оформлении заявки Вы можете уточнить цену либо задать вопросы по нашей продукции.

Описание HELIFLU TZ-N:

Дополнительную информацию на HELIFLU TZ-N Вы можете получить связавшись с нами или отправив заявку на данный товар. При оформлении заявки Вы можете задать вопросы по продукции, запросить цену и т.д.

См. также:

| РП-03 Расходомеры пленочные |

| C MA-A3 Корректоры газа объемные |

| ГКУ 6,3 Установки грузокольцевые |

| ГСБ-400 Счетчики газовые барабанные |

| УППР-500 Установка поверочная |

| ELITE CMF200-RFT9739 Расходомер кориолисовый эталонный |

| 10C1516 Преобразователи расхода турбинные |

| УПСЖ 100 Установки поверочные |

| УЗР-Союз Расходомеры ультразвуковые |

| УПС-500М1 Установки поверочные массоизмерительные |

| ВИР-100, тип расходомеров ВИР-105, ВИР-108, ВИР-11 Преобразователи расхода |

| Метран -360 Расходомеры кориолисовые |

Лидеры продаж Лидеры продаж | ||||||||||

|

Новое в каталоге Новое в каталоге | ||||||||||||||||||||||||||||||

|

Главная

Главная Каталог

Каталог Измерительные приборы и средства измерений

Измерительные приборы и средства измерений Поток, расход, уровень, объем

Поток, расход, уровень, объем Пар, газожидкостные системы

Пар, газожидкостные системы HELIFLU TZ-N

HELIFLU TZ-N

|

|